- Other Fluke companies:

- Fluke

- Fluke Biomedical

- Fluke Networks

- Fluke Process Instruments

How to calibrate your PT100 temperature sensor and other probes in-house

Table of contents

- Why calibrate PT100s and other temperature probes

- Types of temperature probes

- Benefits to calibrating temperature probes in-house

- Challenges to calibrating in-house

- Three ways to calibrate a PT100

- Basic procedures on how to calibrate a temperature probe

Why calibrate PT100s and other temperature probes

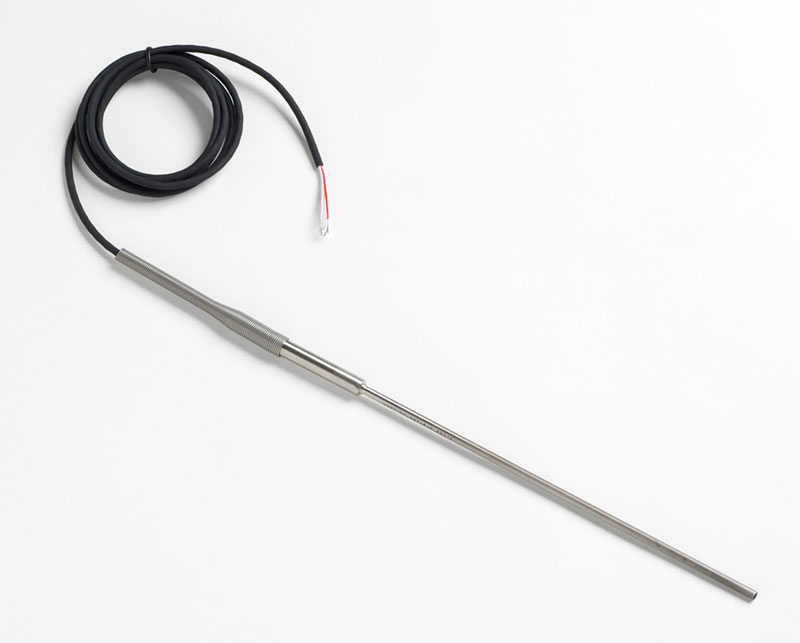

Thermometer probes like PT100s, PRTs, and RTDs need to be calibrated regularly. Temperature is always on the move through time, meaning any probes that are measuring temperature need to be calibrated to be accurate. If your work requires a specific temperature or range, then you need to be calibrating your thermometers and probes throughout their lifecycle.

Types of temperature probes

These three types of thermometer probes are all sensors or are sensors whose resistance changes as the sensor’s temperature changes. If the temperature increases, the resistance increases.

- PRT stands for Platinum Resistance Thermometer

- RTD stands for Resistance Temperature Detector

- PT100 thermometers are a specific subset of PRTs; the nominal resistance at zero is 100 ohms

Benefits to calibrating temperature probes in-house

- Save Money. In-house calibration, or internal calibration, is when a company chooses to invest in the hardware, employees, and time to complete a calibration on their own premises instead of sending instruments out to a third-party lab. In-house calibration can save time, and money, because the amount of downtime experienced will be limited. Instead of having to remove and send an instrument out, you can complete the calibration and reinstall it quicker. You’ll also eliminate 3rd-party calibration bills.

- Reduce Downtime. Mitigating downtime extends to unexpected calibration needs. By having the support in-house, the team is readily available to help with issues that arise–again, cutting downtime to a minimum.

- Calibrate Quicker. Along that same vein, if an instrument’s measurement or reading is off, it can be detected immediately, isolating the process affected, and fixed quicker. By having the measurement and calibration knowledge within the team, a non-conforming measurement can be assessed and dealt with.

- Reduce Probe Damage. By doing the work in the same location the instrument is used in, you reduce the risk of problems created during transport. Shipping instruments back and forth has a risk of vibrations, dropping, or other environmental stress being absorbed. Instead of taking on these risks and uncertainty, you increase your assurance in the stability of the calibration work in-house. Bringing the calibration in-house also offers an additional safety feature. Because the instrument or parts around it do not need to be transferred, the risk is reduced or eliminated entirely.

Challenges to calibrating in-house

While there are many benefits to calibrating your temperature probes in-house, there are also some challenges to overcome. In many situations, once the internal calibration laboratory is established, keeping it running smoothly becomes much easier and more manageable.

One of the challenges that faces companies thinking about creating their own calibration program is the upfront cost. It does require knowledgeable calibration personnel, investing in the right equipment, setting up a laboratory facility, and purchasing the master or reference standards. However, depending on calibration volume, it can be easy to justify the initial startup cost by comparing it with how much you spend to outsource the calibration of each asset in your facility. Talk with one of our calibration experts to calculate an ROI for your situation.

Both finding the right personnel to hire for the job, and keeping up with the training to become calibration experts is an additional cost. Fluke Calibration does offer metrology and certification training courses to get individuals up to speed, and the courses offered cover a wide range of calibration needs you may come across:

- Electrical calibration

- Calibration software

- Temperature calibration

- Pressure calibration

- Flow calibration

You should also consider availability of service and support for any equipment you purchase. Fluke Calibration offers support via online chat, email, telephone and through our service organizations. We also offer routine calibration and repair services.

Three ways to calibrate a PT100

Depending on where your PRTs are located throughout your facility, there are a few different ways to calibrate them. As you go down the options, each one offers a more precise calibration than the previous.

1. Process calibrator

A process calibrator, like the Fluke 754 Documenting Process Calibrator with HART Communication, can be the first line of defense in calibrating PT100s in the field. The process calibrator class offers a portable option for calibrating, maintaining, and troubleshooting a few types of assets. The system downloads procedures and instructions created with software. It can also upload data for printing, archiving, and analysis, even storing a full week of downloaded procedures and calibration results.

The process calibrator is a great first step in keeping your RTDs calibrated, but they will not offer the precision you get from higher level calibration tools. A typical process calibrator only simulates a sensor to check the sensor readout or indicator which is often a 4 to 20 mA transmitter system like the one shown here. To check the sensor with an actual temperature calibration you will need to incorporate a temperature calibrator. Some of Fluke’s process calibrators can work directly with a temperature calibrator to help automate and document the calibration.

2. Dry-block calibrator

The next step in the calibration hierarchy for temperature probes is a dry-block calibrator. These calibrators are not as portable as process calibrators, but they are still easier to move around than bath calibrators. They are fast, clean, and often popular for on-site sensor calibrations in process manufacturing.

Dry-block calibrators offer an incredibly stable temperature source for calibrating many different temperature sensors, including PT100s. There are three things to keep in mind when selecting a dry-block calibrator:

- What is the size and type of the temperature sensors?

Not all temperature probes will work well with dry-block calibrators. Since a dry-block offers specific sized wells, not all probes will fit.

- What temperature range is needed?

Different dry-block calibrators offer different temperature ranges and different features for calibration. It’s important to know what range you’re looking for, and what features you need, so you have the right equipment for your needs.

- What calibration accuracy is required?

In the same way that not all temperatures are represented by all calibrators, not all accuracy ranges can be guaranteed by all calibrators. Finding the dry-block calibrator that can ensure your temperature probes are measuring to the accuracy you need is important.

3. Calibration baths

For PT100 probes that have a challenging shape or size, or require higher level calibration, a calibration bath may be the right option. This method is the least portable of the options listed here, but it offers the most flexibility in the calibration method. A calibration bath can use a stirred fluid, like water, silicone oil, ethanol, or methanol. Using these liquids creates an extremely stable and uniform temperature for accurate sensor calibration. Fluke Calibration’s baths are designed so multiple probes can be calibrated, with the same precision, at the same time.

Now that we’ve looked at 3 ways to calibrate, let’s look at a temperature sensor calibration procedure.

Basic procedures on how to calibrate a temperature probe

To calibrate a PRT, PT100, or RTD using a dry-block calibrator or calibration bath, there are five steps you usually need to follow:

- Place the reference probe and the probe you’re calibrating in the temperature source. Try to keep them close together, in a circle, with the reference probe in the center.

- Connect the leads to the readout that measures the probes. This may be the calibration readout or it may be the readout that is paired with the probe.

- At each test point, measure and record the reference probe temperature and the temperature of the probe you’re calibrating as well as the equipment settings. In higher level PRT calibration you may need to measure probe resistance also so new adjustment parameters can be calculated as part of the calibration.

- Verify the DUT error to know if it is in tolerance or not.

- If necessary, use the calibration results to calculate new adjustment parameters for the probe being calibrated. This is the process of solving a set of equations that contain the calibration data to find a set of coefficients unique to the RTD and calibration. It’s easiest to invest in software that can do this.

Learn more about calibrating your PT100s in-house

There are many different ways to calibrate your temperature probes; to learn what method is best for your needs and whether it makes sense to calibrate in house, contact one of our calibration experts.

- Home

- Products

- New Products

- Electrical Calibration

- RF Calibration

- Data Acquisition and Test Equipment

- Temperature Calibration

- Humidity Calibration

- Pressure Calibration

- Flow Calibration

- Process Calibration Tools

- Calibration Software

- Service and Support

- All Calibration Instruments

- Handheld Test Tools

- Purchase Info

- News

- Training and Events

- Literature and Education

- Service and Support

- About Us