- Other Fluke companies:

- Fluke

- Fluke Biomedical

- Fluke Networks

- Fluke Process Instruments

Rotameter Calibration

A rotameter, also called variable area flowmeter, is inherently a volumetric flow measurement device. The word origin is rota(tion) + messer/measure/meter. The scale can be in mass flow units if the volume flow rate is multiplied by a specified density, and in dimension units (mm) or percent.

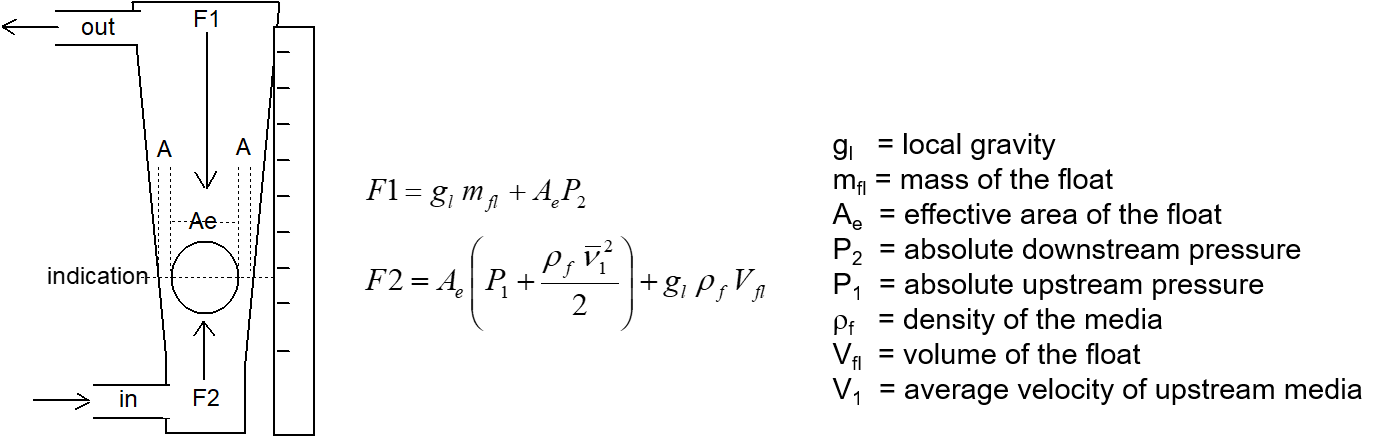

An indicator floats at a steady value when the forces on it are equal. The main forces are the weight of the float (downward) and the drag force of the fluid (upward). Other forces are the difference in pressure over the float and the buoyancy force of the displaced fluid, which increases with pressure. The static equilibrium of the float is defined by the weight of the float, the drag, and the buoyancy force on the float.

Ideally, a rotameter is designed and calibrated at the same temperature and pressure, and with the same process gas, for which it will be used. This ensures that the density of the gas is the same, although it is often too difficult to replicate the exact conditions of use. Also, calibrating in the actual gas is recommended, but some gases cannot be used due to the fact that they may not be supported due to lack of flow references or the gas may be hazardous, such as Oxygen (O2), which is flammable, or carbon monoxide (CO), which is toxic.

To account for non-ideal conditions, calculations can be made to modify the reference flow from the conditions during the calibration to the scale conditions of the rotameter.

Why rotameter calibration is important

A rotameter is typically designed for one specific gas density and flow range, so without the rotameter being calibrated to those conditions, accuracy will suffer. Calibrating a rotameter will identify the reference conditions in which the rotameter will be used, thus offering the most precise measurements.

What you need to calibrate a rotameter

- Calibration gas supply: dried, filtered.

- Regulators – line pressure reducing: designed to reduce a higher supply pressure to a lower test pressure, such as 50-600 kPaa or 200-2000 kPaa.

- Regulators – back pressure: designed to maintain, hold back, or increase a pressure upstream of it, with a lower pressure on the outlet (vacuum or atmosphere).

- Flow control hardware, one of the following:

- Needle valves

- Mass flow controllers

- Pressure regulators

- Data acquisition – manual or automated: Fluke’s COMPASS for Flow software or Excel.

- Flow reference, one of the following:

- Fluke molbox/molbloc: portable; automation capabilities.

- Piston provers: can be semi-automated; Mercury seal hazard; not portable.

- Bell provers: not portable; not automated.

- Gravimetric system: not portable; far more accuracy than typically needed.

- “Golden” reference: another rotameter, mass flow device, LFE, or sonic nozzle.

- Gas conditions

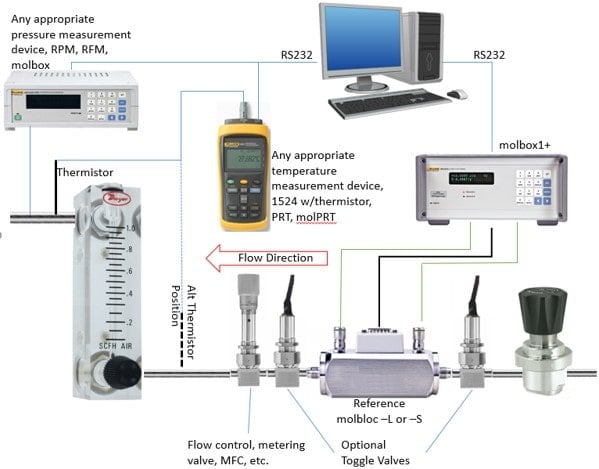

- Temperature measurement device: A relatively fast reacting temperature probe is recommended, such as a Fluke 5610 thermistor probe with a Fluke 1523 or 1524 Digital Readout. The temperature from the molbloc can be used, but molblocs are rarely calibrated for temperature after the initial calibration (and the temperature of the molbloc must be the same as that of the rotameter, however it may not be if there is a restriction between them).

- Pressure measurement device: An appropriate digital ABSOLUTE pressure gauge or monitor is recommended, such as a molbox1+, a Fluke RPM4, a lab barometer, or any decent digital pressure device at the outlet of the rotameter and upstream of any downstream regulator.

- Digital instruments for temperature and pressure are recommended as they can be interfaced with a PC for data collection.

- Level: the rotameter must be perpendicular/level to achieve the best results.

- The float is in a constant balance or equilibrium of the flow against gravity – any significant misalignment can cause inaccuracies and/or cause the float to touch the tube walls.

- Thermistor or PRT insertion: never use metal ferrules; standard fittings have a lip to prevent tube ends from intruding too far.

How to connect/adapt the flow path to the rotameter

It is very common to see NPT adapted to other connectors. NPT uses Teflon tape, which far too commonly winds up in the flow path, resulting in the contamination of the rotameter or the flow reference. What is not recommended, but very common, is the adaptation of the NPT down to an unreasonably small connection that restricts flow (e.g., 1” NPT adapted to ¼” or 1/8” Swage fittings).

Significant thought should be put into adaptors and where to measure pressure and temperature. Measuring pressure and temperature AFTER a significant connector adaptation will not give the true operational conditions in the rotameter tube. It is always recommended that pressure and temperature measurements be as close to the original exit (or entrance) of the rotameter as possible.

How to calibrate a rotameter

Follow this rotameter calibration procedure, step by step.

Step 1. Start the flow of gas. Fluke recommends starting at the highest flow and working down. This results in better purging of the calibration gas, and better results at the lower flows.

Step 2. Adjust the flow control/regulators to get to the test point.

Step 3. Allow time for flow, pressure, and temperature stabilization. Initial adiabatic processes will cause all of these to change—allow time in between adjustments for settling.

Step 4. Record the rotameter indication (read the rotameter float from the uppermost largest diameter), the reference flow, and the gas pressure and temperature.

Step 5. Convert to mass flow and apply the appropriate square root density correction, then convert back to the scale flow units and conditions.

- Convert reference and DUT (Device Under Tester) flows to mass flow of the calibration/surrogate gas (the actual gas being flowed); SCFH to mg/s:

- qm = Gas Density (ATM Pa, 0°C, 0 RH) X Flow / 6E7 / 3.53147E-5 / 60

- Apply the inverse mass flow square root density correction to the reference.

- Convert this reference flow to the rotameter design gas at design conditions; mg/s to SCFH:

- SCFH = 6E7 / Gas Density (act Pa, act °K, 0 RH) * Flow * 3.53147E-5 * 60

- Note that volumetric corrections do not work as well when using a surrogate gas. No corrections work well if the surrogate is not similar to the design gas.

Four ways to calibrate the same rotameter

Rotameter Scaled for Air

- 30 SCFH near scale conditions

- 30 SCFH at elevated conditions

- 30 SCFH using a surrogate gas (Argon)

- 30 SCFH using a surrogate gas (Argon) at elevated conditions

In each scenario below actual COMPASS for Flow calibration software reads the actual gas pressure and temperature and calculates the gas density.

Scenario: 30 SCFH near scale conditions

The five measurements and the calculation at 30 SCFH near scale conditions are:

- molbloc reading: 31.8686 SCFH

- Actual gas pressure: 97.426 kPaa (scale 101.325)

- Actual gas temperature: 23.333 °C (scale 21.1 °C)

- (ρf)design Scale/design gas density: 1.199756 kg/m3 air

- (ρf)actual Actual gas density: 1.144862 kg/m3 air

Square root density correction:- Mass flow correction

FVA = √((ρf)actual / (ρf)design ) = 0.976855 - Volume flow correction

FVA = √((ρf)design / (ρf)actual ) = 1.023693

- Mass flow correction

| Rotameter Flow | molbloc Flow | % Rdg Error | % FS error | ||

| No correction* | 30.000 | 33.397 | -10.17 | -6.79 | Actual (ACFH) flow, not SCFH |

| Rotameter corrected* | 30.711 | 33.397 | -8.04 | -5.37 | ACFH with correction to rotameter |

| molbloc corrected* | 30.000 | 32.624 | -8.04 | -5.25 | SCFH with inverse correction to molbloc. This is how COMPASS for flow reports. |

| Rotameter corrected | 29.306 | 31.869 | -8.04 | -5.13 | SCFH with correction to rotameter |

| molbloc corrected | 28.627 | 31.131 | -8.04 | -5.01 | SCFH with inverse correction to molbloc. |

*A rotameter is ALWAYS subject to actual conditions, regardless of the scale flow unit stating “S”CFM.

Scenario: 30 SCFH at elevated conditions

- molbloc reading: 43.808 SCFH

- Actual gas pressure: 183.686 kPaa (scale 101.325)

- Actual gas temperature: 23.736 °C (scale 21.1 °C)

- (ρf)design Scale/design gas density: 1.199756 kg/m3 air

- (ρf)actual Actual gas density: 2.156153 kg/m3 air

- Square root density correction:

- Mass flow correction

FVA = √((ρf)actual / (ρf)design ) = 1.144703 - Volume flow correction

FVA = √((ρf)design / (ρf)actual ) = 0.873589

- Mass flow correction

| Rotameter Flow | molbloc Flow | % Rdg Error | % FS error | ||

| No correction* | 30.000 | 28.466 | 5.39 | 3.07 | Actual (ACFH) flow, not SCFH |

| Rotameter corrected* | 26.208 | 28.466 | -7.93 | -4.52 | ACFH with correction to rotameter |

| molbloc corrected* | 30.000 | 32.585 | -7.93 | -5.17 | SCFH with inverse correction to molbloc. This is how COMPASS for flow reports. |

| Rotameter corrected | 34.341 | 27.03 | 27.05 | 14.62 | SCFH with correction to rotameter |

| molbloc corrected | 39.310 | 30.942 | 27.05 | 16.74 | SCFH with inverse correction to molbloc. |

*A rotameter is ALWAYS subject to actual conditions, regardless of the scale flow unit stating “S”CFM.

Scenario: 30 SCFH, surrogate gas, elevated conditions

- molbloc reading: 35.174 SCFH Argon

- Actual gas pressure: 163.896 kPaa (scale 101.325)

- Actual gas temperature: 23.585 °C (scale 21.1 °C))

- (ρf)design Scale/design gas density: 1.199756 kg/m3 air

- (ρf)actual Actual gas density: 2.656540 kg/m3 Argon

- Square root density correction:

- Mass flow correction

FVA = √((ρf)actual / (ρf)design ) = 1.488030 - Volume flow correction

FVA = √((ρf)design / (ρf)actual ) = 0.672030

- Mass flow correction

| Rotameter Flow | molbloc Flow | % Rdg Error | % FS error | ||

| No correction* | 30.000 | 21.921 | 36.85 | 16.16 | Actual (ACFH) flow, not SCFH |

| Rotameter corrected* | 20.161 | 21.921 | -8.03 | -3.52 | ACFH with correction to rotameter |

| molbloc corrected* | 30.000 | 32.620 | -8.03 | -5.24 | SCFH with inverse correction to molbloc. This is how COMPASS for flow reports. |

| Rotameter corrected | 44.641 | 35.174 | 26.91 | 18.93 | SCFH with correction to rotameter |

| molbloc corrected | 66.427 | 52.341 | 26.91 | 1628.17 | SCFH with inverse correction to molbloc. |

*A rotameter is ALWAYS subject to actual conditions, regardless of the scale flow unit stating “S”CFM.

Calibrating to the scale gas

| Rotameter SCFH | molbloc SCFH | % Rdg Error | % FS Error | |

| 30 | 32.624 | -8.04 | -5.25 | Air close to scale conditions |

| 30 | 32.678 | -8.20 | -5.36 | Air elevated conditions |

| 30 | 32.585 | -7.93 | -5.17 | Argon as surrogate close to scale conditions |

| 30 | 32.620 | -8.03 | -5.24 | Argon as surrogate at elevated conditions |

The results are all beyond the 5% FS specification for this rotameter. This rotameter scale is not adjustable; a table, chart, or calibration curve would need to be generated to use this rotameter within specifications. Some rotameters have an adjustable metal scale next to the tube, rather than the scale permanently printed on the tube.

Rotameter Calibration Tips

- Fluke recommends leaving the rotameter indication uncorrected and applying the inverse correction to the molbloc. This keeps the cardinal point of the rotameter scale while still reporting the relative difference from the reference.

- Results will not be the same if calibrating a rotameter to be used with a different gas. If using a surrogate gas, use one close in density to the design gas when possible

For rotameter calibration service, you can look to one of many 3rd-party calibration labs. Fluke Calibration has an advanced lab that can calibrate your rotameter as well. See the following video that demonstrates how our lab utilizes the Fluke molbox and molbloc to calibrate rotameters:

Rotameter calibrators

If you have several instruments that you send out for calibration, you might consider the business case and ROI for purchasing a rotameter calibrator or calibration system such as the Fluke molbox and molbloc and performing the calibrations in house.

When researching rotameter calibrators, look for the following features and capabilities:

- Flow Reference at least two times more accurate/lower uncertainty than the rotameter

- Flow Adjustment hardware

- No moving parts – a constant volume provides the best conditions for stable flow rates

- Line Pressure Regulator/optional Back Pressure Regulator to establish pressure at which to calibrate the rotameter

- Pressure and temperature measurement instruments to capture calibration conditions

- Software to calculate corrections that account for differences between calibration conditions vs. conditions for which the rotameter is designed

- Miscellaneous hardware – Tubing, adapters, shutoff valves.

Keep learning

- Calibrating Rotameters and other volumetric flow meters - webinar

- Rotameter calibration example using Fluke Compass software including a link to a Calibration Test Report – support article

- Flow meter calibration: five best practices you need to know – blog post

See related products

- molbox1+ Flow Terminal

- molbloc-L Laminar Flow Element

- molbloc-S Sonic Nozzle Calibration Device

- COMPASS for Flow Software

Get help

- Customer and technical support

- Speak with a calibration product expert about your equipment needs

- Home

- Products

- New Products

- Electrical Calibration

- RF Calibration

- Data Acquisition and Test Equipment

- Temperature Calibration

- Humidity Calibration

- Pressure Calibration

- Flow Calibration

- Process Calibration Tools

- Calibration Software

- Service and Support

- All Calibration Instruments

- Handheld Test Tools

- Purchase Info

- News

- Training and Events

- Literature and Education

- Service and Support

- About Us