- Other Fluke companies:

- Fluke

- Fluke Biomedical

- Fluke Networks

- Fluke Process Instruments

5560A Multi-Product Calibrator key technologies and features Application Note

The 5560A High Performance Multi-Product Calibrator defines a new class of multi-product calibrator, providing the broadest electrical workload coverage and highest accuracy for calibrating the most demanding modern workloads.

In creating this new class of calibrator, Fluke Calibration engineers developed multiple new technologies that make the 5560A, 5550A, and 5540A all powerful multi-functional tools in the electrical calibration laboratory. Plus, these instruments are delightfully easy to learn and to use.

30 A Class D transconductance amplifier

The 5560A, 5550A and 5540A include 30 A continuous current output with no duty cycle, an innovation that was one of the most technically difficult to accomplish.

Continuous current output reduces wait time during heavy usage because the amplifier doesn’t overheat. With other calibrators, how long you can operate has a limit meaning you then have to let the calibrator cool down for a certain amount of time (based on how long you had it turned on). You could be required to turn off the calibrator for seven minutes for every minute of time in-use. Now, with the 5560A you can calibrate modern benchtop multimeters and clamp meters with less wait time and better throughput.

Visual Connection Management™ connection terminals

Visual Connection Management™ output terminals light up to show you which terminals are active, guiding the user to make the correct connections. New in the 5560A, 5550A, and 5540A, the terminals light up in green for voltage and blue for current, making it even easier to match the right connection to the measurement you’re making.

Output block design

We’ve re-mapped the output terminals on the 5560A, 5550A, and 5540A to match the terminals’ layout on standard digital multimeters. This makes it possible to calibrate this type of workload with minimal lead changes. You can also stack connectors when testing meters if you want to do 4-wire ohms measurements.

The new terminal layout marks a distinct improvement over older models. The 5522A, for example, has shared Sense and AUX terminals, as well as shared ground and guard, so you have to change leads frequently during a multimeter calibration. On the 5560A, 5550A, and 5540A, all the terminals are dedicated, and the guard terminal is moved to the side, enabling you to connect the leads once and complete the meter calibration efficiently.

AUTOCAL DMM Lead Set (Optional)

For labs with a large workload of digital multimeters, the AUTOCAL DMM Lead Set can be a real time saver. The adapter plugs directly into the calibrator’s output terminals and minimizes, or in some cases eliminates, the need for lead changes. Increase throughput and also reduce the possibility of user error.

To really increase your productivity, automate with MET/CAL™ calibration software. When paired with the AUTOCAL DMM Lead Set, you just need to plug in the accessories, making the initial connections, run the procedure, and walk away.

Intuitive user interface

A 17.8 centimeter (7-inch) graphical user interface offers intuitive menus that are easy to navigate and read, providing access to common functions with the touch of a finger and eliminating the menu scrolling that was required in previous 55XXA models.

The screen displays all the information you need for each parameter you’re calibrating, with color-coded fields that make it easy to see where you enter data. The menu is simplified, and functions are laid out consistently across the 5560A, 5550A, and 5540A, so that once you learn how to operate one you know how to operate them all. Training new users just became easier.

Status indicators for OPERATE, STANDBY, and HAZARDOUS VOLTAGE appear on the screen in bright letters or icons you can recognize from across the calibration lab.

The touch screen interface is available in nine languages, including English, French, German, Spanish, Japanese, Chinese, Portuguese, Russian, and Korean.

Performance improvements

Multiple technical improvements have been built into the 5560A, 5550A, and 5540A to improve performance.

1000 V direct amplifier

The amplifier reduces the use of transformers to generate high AC voltages. Eliminating transformers helps to reduce the size and weight of the calibrator, making on-site calibration easier and allowing our engineers to pack more features into the instrument without significantly increasing weight.

With our older multi-product calibrators, we generated our high voltages with a transformer; the ones that work at low frequencies are large and bulky. The old calibrator could only test down to 45 Hz. Specified performance on the 5560A drops the frequency down to 3 Hz. Extending the high voltage output to low frequency extends workload coverage to a wider range of instruments.

Digital-to-analog converter (DAC) linearity design independent of switch resistance

This technical innovation helps to reduce errors and improve 5560A performance for accurately calibrating 6.5-digit multimeters.

New and improved synthesized impedance technology

The 5560A electronically simulates inductance, so you can easily select a wider range instead of switching between preset values. You just dial in the exact value you want within the specified range. This innovation helps to improve performance and enables broader workload coverage.

Improved thermocouple input/output mechanical/ thermal design

By reducing settling time, this design improvement helps to increase productivity and reliability because you don’t have to wait as long for friction heat to dissipate after making the connection. Additionally, the new design lets you measure a wide variety of thermocouples, whether they have a large or small connector, or even if they just have bare wires.

“Cable-free” system architecture

This type of system architecture removes most internal cables from the motherboard, so there are fewer cables to pop loose, thus making the calibrator easier to repair.

The architecture also features an independent AC power supply that helps to eliminate noise and enhances performance. You’ll get a better noise floor due to this improvement.

On-board oversized circuit

This circuit replaces large, expensive ovens by providing thermal isolation on the printed circuit board (PCB). It helps to keep the calibrator’s internal temperature stable, which gives you more control over your tests.

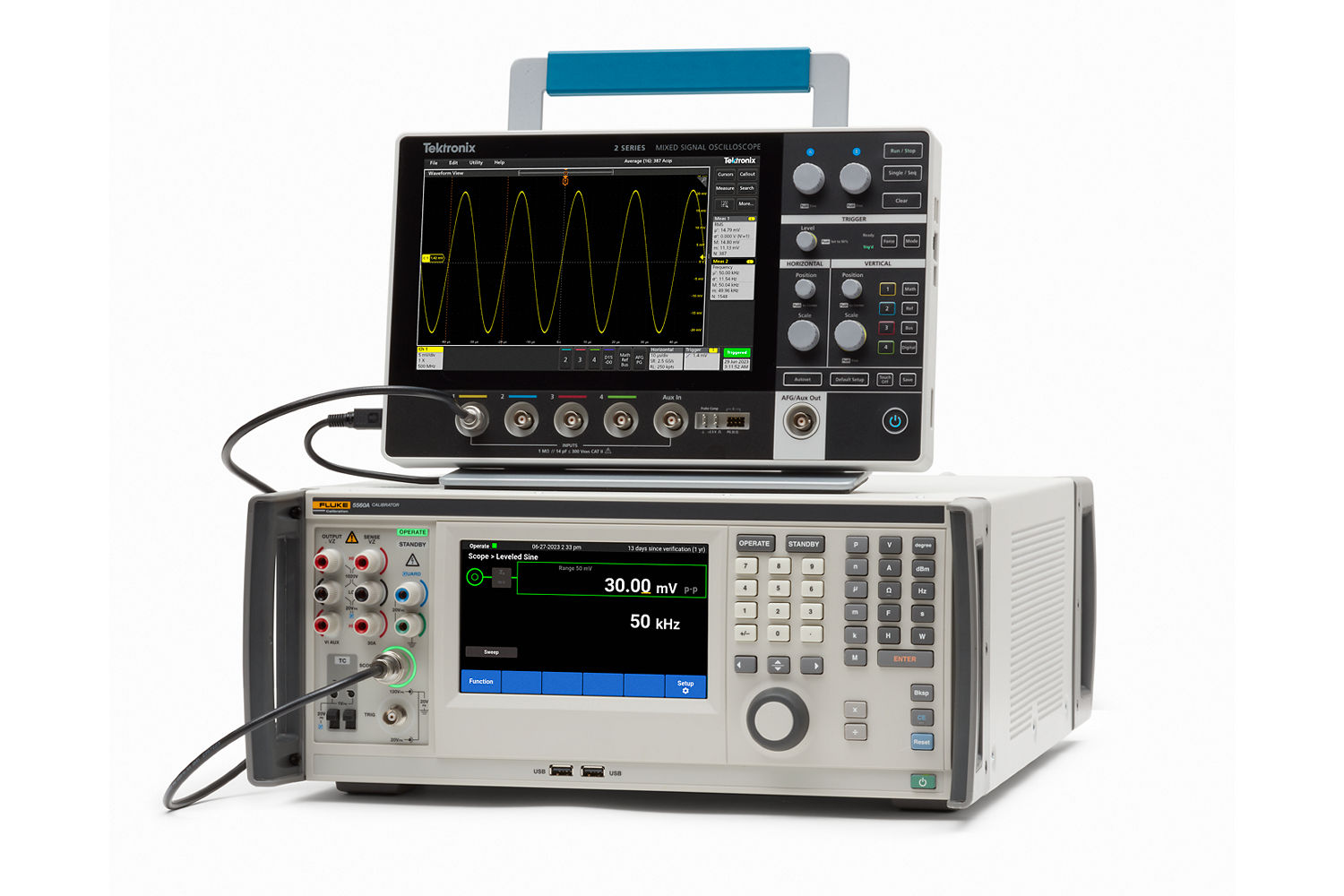

Oscilloscope calibration

With the oscilloscope calibration option, the 5560A, 5550A, and 5540A add to, and expand upon, what previous multi-product calibrators could tackle. Fluke Calibration engineers designed an accurate RF voltage source to have everything you would need to calibrate an oscilloscope, including a fast edge, DC and LF electrical functions, markers, and frequencies of more than 1 GHz range in both the 5550A and 5560A.

| 600 MHz | 1 GHz | 2 GHz | |

| 5560A | ✓ | ✓ | ✓ |

| 5550A | ✓ | ✓ | |

| 5540A | ✓ |

Improved internal digital communication

Using Ethernet technology, we have improved the robustness and stability of the internal communications to reduce the possibility of electrostatic discharge that might cause the calibrator to lock up.

Common instrument architecture

This is a forward-looking feature, first implemented on the 5560A, 5550A and 5540A. It refers to an application layer that will be common for all new Fluke Calibration products. Having a common architecture will reduce training time as each instrument will have the same basic interface and operating procedures. Adjusting from one to the next will be easier on technicians.

- Home

- Products

- New Products

- Electrical Calibration

- RF Calibration

- Data Acquisition and Test Equipment

- Temperature Calibration

- Humidity Calibration

- Pressure Calibration

- Flow Calibration

- Process Calibration Tools

- Calibration Software

- Service and Support

- All Calibration Instruments

- Handheld Test Tools

- Purchase Info

- News

- Training and Events

- Literature and Education

- Service and Support

- About Us